Topic Sustainability, Carbon, Supply chain

Date 06 Jul 2023

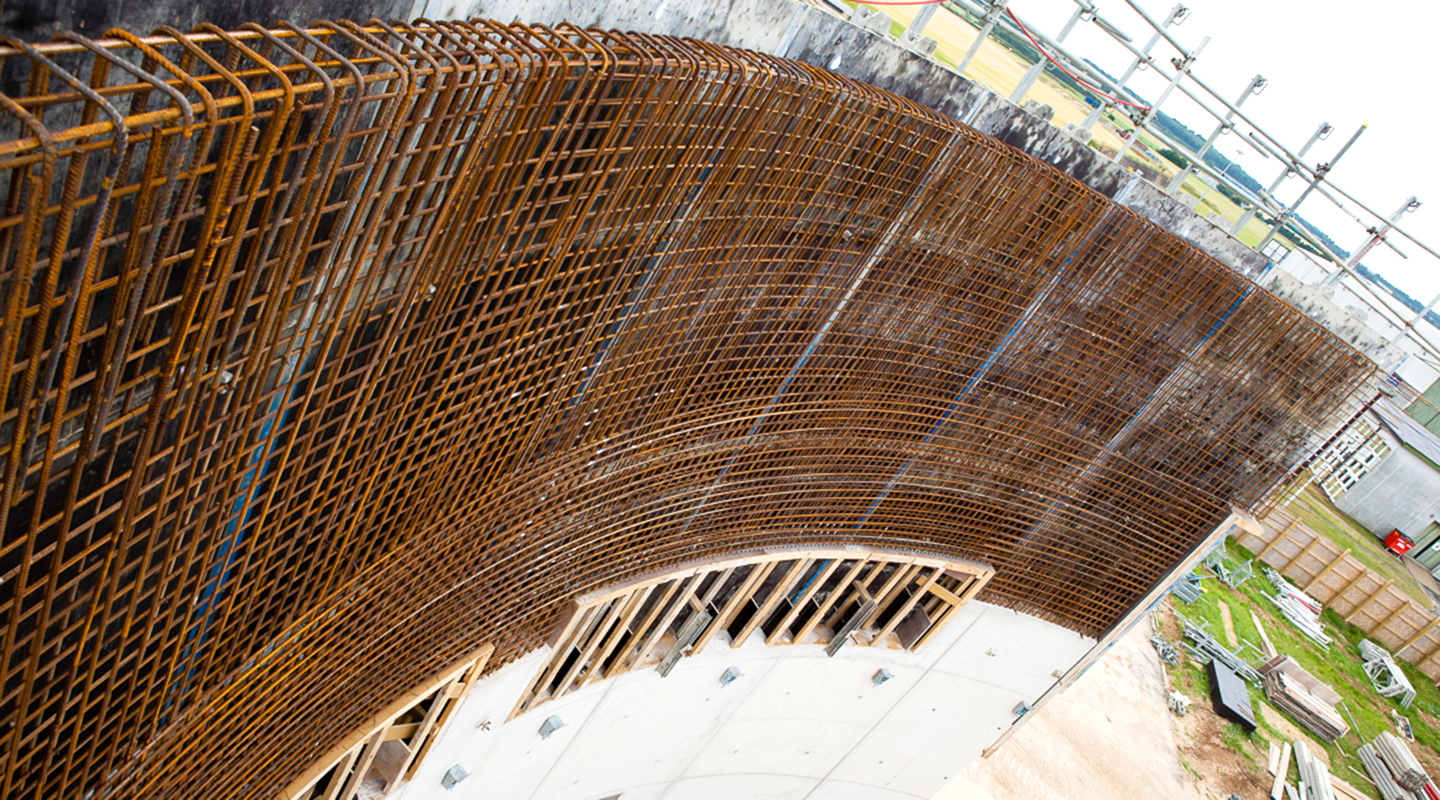

Morrison Construction, part of Galliford Try, has opted to use lower carbon Electric Arc Furnace (EAF) steel, on all future educational projects, assisting in the drive to help clients hit their embodied carbon targets.

The move has come as a direct result of Galliford Try’s Net Zero Partners programme, where the business collaborates with members of its supply chain to help assist in reaching everyone’s Net Zero targets, through education and information sharing. Galliford Try has pledged to achieve Net Zero carbon across its own operations by 2030, and Net Zero across all activities by 2045 at the latest.

The manufacturing method of EAF steel significantly reduces the use of fossil fuels over Blast Furnace Basic Oxygen Furnace by using electrical processes and utilising higher percentages of recycled content. Up to a 77% saving on carbon can be created compared to its traditional counterpart.

The first scheme to feature an EAF frame is the Easthouses Primary School project for Midlothian Council.

Allan Smith, Low Carbon Manager for Morrison Construction commented: “This is a positive further step by the business to meet our net zero targets, reducing the embodied carbon in what is a major constituent part of many projects. We are also delighted that this change came about through direct engagement in our Net Zero Partners programme, proving that by collaborating together as an industry, we can better solve the challenges of the future.”

Galliford Try pledged to achieve net zero carbon across its own operations by 2030, and net zero across all activities by 2045 at the latest. The Group received validation for its ambitious carbon reduction targets from the UN-backed Science Based Targets initiative (SBTi).